The equipment is for fully automated production of electrochemical polishing. The entire process (such as electrolytic polishing, cleaning, passivation, neutralization) is completed automatically, and all operations can be performed on the touch screen, without direct contact by personnel, reducing the possible harm to the operating staff during the process. The parameters of the execution module can be stored, which is convenient for retrieval and use, and the production efficiency is high.

It is especially suitable for occasions with limited types and mass processing.

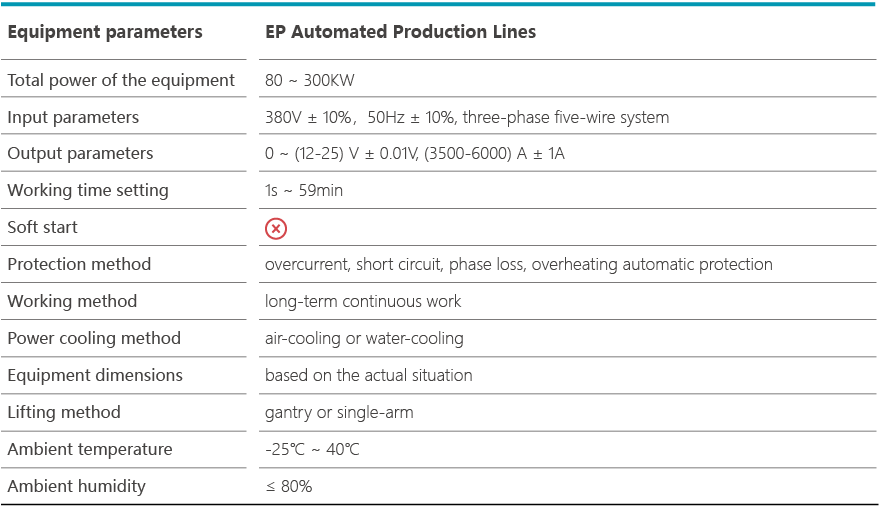

The automated production line consists of two types: single-arm type and gantry type, according to the processing volume of a single batch. The single-arm type can be used in the occasions with a small processing volume and continuous processing and production; the gantry type is suitable for the case with a large processing volume or a sizable single workpiece.

Features:

1. The processing production line can be a fully automatic production process, greatly reducing labor intensity, operating staff, operating risks, and production costs;

2. The electrochemical polishing solution adopts the environment-friendly formula and does not contain heavy metals (hexavalent chromium), which greatly reduces the harm to the environment. The sewage treatment cost is low and can be certified by ROHS; it has low energy consumption, long life and lower cost;

3. The tank body is made of high-quality PP, PVD or stainless steel. The tank body has heat resistance and corrosion resistance. The exterior is reinforced with a steel structure to ensure the long-term service life of the equipment;

4. The operation is all carried out on the touch screen, and has two modes for users to choose: automatic and manual;

5. The set parameters can be saved to ensure that the mature processing technology can be retrieved and easy to use;

6. The user levels corresponds to different permissions. A user can access with the corresponding password, which is safe and convenient for management;

7. The production line has program saving function for power failure or other fault alarms. After the power is restored and the fault is removed, the subsequent program can continue to be executed;

8. The electrical control accessories are all made by Schneider, Omron, Fuji and other large manufacturers, with reliable quality and stable performance;

9. The electric heating uses heaters with materials of PTFE, pure titanium, stainless steel and others, which can be designed in accordance with customer demands. The structure is compact and the heating effect is good; constant temperature control, flow water circulation, adjustable temperature in each tank, water level control, heat protection;

10. The anode and cathode materials can be made of copper, aluminum, stainless steel, graphite, lead and other materials in accordance with the customer demands, and metal titanium with strong acid resistance is used as the processing hanger, which has a long service life and low operating cost.

11. System matching functions: ultrasonic cleaning, online detection of potion proportion, acidity, and PH value, electrolytic polishing solution circulating filtration system, acid mist recycling system, power supply protection system;

5. 摘要 Summary 鉴于大量的影响参数和由此产...

4.3 电化学(阳极)清洗 Electrochemical (anod...

4.2 化学去除方法 Methods of chemical remova ...

3. 清洁和维护 腔室 Cleaning and m...

时间:2023年9月22日 地址:浙江温州温德姆酒...

Equipment Sales:

Mr. Wang: +86-15921887786

Mr. Li: +86-18017268222

Processing Service:

Ms. Zhang: 18001952488

Ms. Long:13386001718

Add.: No. 8 Xinshun Road, Zhujing Industrial Park, Zhujing Town, Jinshan, Shanghai, China

Email:

sales@mirrorglabrous.com