Electro-plasma polishing is a process that under high temperature and high pressure, electrons from the polishing agent escape from the nucleus, and then the nucleus form a positively charged ion, and when these ions reach a certain number, they become a plasma state. The energy of the plasma state is very large. When these plasmas rub against the object to be polished, the object will be instantly illuminated.

Electro-plasma polishing is a new metal surface treatment process. Compared with other polishing methods, electro-plasma polishing has very high quality, fast speed, and low cost that cannot be achieved through traditional methods, while the raw materials used in the process do not contain chemicals (polishing salts) that pollute the environment or harm the health of the producers.

Applicable materials: all conductive materials such as stainless steel, titanium, aluminum, copper, silver, zinc and alloys.

It improves production efficiency and reduce production costs: easy to deburr the holes and solve other surface polishing problems, the polishing process is within a few minutes, greatly reducing the labor;

The process is fully automatic control, easy to operate;

The process is safe and stable, simple maintenance: equipped with protection sensor to prevent accidents, user-friendly design, convenient maintenance and inspection;

The polishing has a high degree of uniformity, as the surface of each piece and each batch of workpieces is not affected by human, and this enables consistent mirror effects on workpieces.

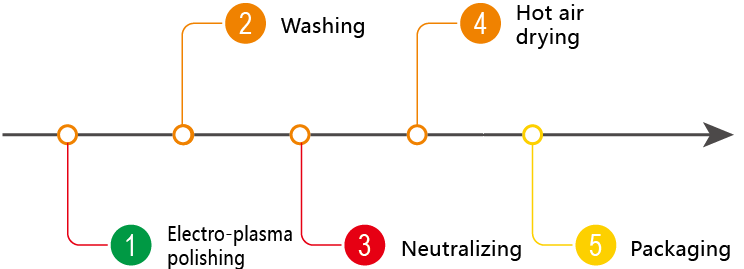

Process of electro-plasma polishing:

5. 摘要 Summary 鉴于大量的影响参数和由此产...

4.3 电化学(阳极)清洗 Electrochemical (anod...

4.2 化学去除方法 Methods of chemical remova ...

3. 清洁和维护 腔室 Cleaning and m...

时间:2023年9月22日 地址:浙江温州温德姆酒...

Equipment Sales:

Mr. Wang: +86-15921887786

Mr. Li: +86-18017268222

Processing Service:

Ms. Zhang: 18001952488

Ms. Long:13386001718

Add.: No. 8 Xinshun Road, Zhujing Industrial Park, Zhujing Town, Jinshan, Shanghai, China

Email:

sales@mirrorglabrous.com