Electrochemical-mechanical abrasive polishing is a composite process combines electrochemical abrasive polishing and mechanical abrasive polishing. During electrochemical abrasive polishing, the abrader serves as the cathode and the tool for abrasive polishing, and the workpiece is the anode; the electrolyte is usually formulated based on saline solution.

Electrochemical-mechanical abrasive polishing is suitable for stainless steel, aluminum alloy, titanium alloy, nickel alloy, magnesium alloy, hastelloy alloy, copper alloy, carbon steel, bearing steel, die steel, and other materials.

The abrasive speed of a workpiece is mainly determined by the effect of electrochemical abrasive polishing. Therefore, under the same surface roughness, the effect of the electrochemical process is higher than the mechanical process, and there are no remaining burrs on the workpiece after electrochemical abrasive polishing.

An electrochemical-mechanical abrasive polishing process can make a workpiece surface roughness reach mirror effect, Rz 0.2~0.01μm, from a roughness of Rz 10~20μm. When the abrasive condition is adjusted, the surface roughness can reach an ultra-mirror degree, Ra 0.001μm(Ra=1nm).

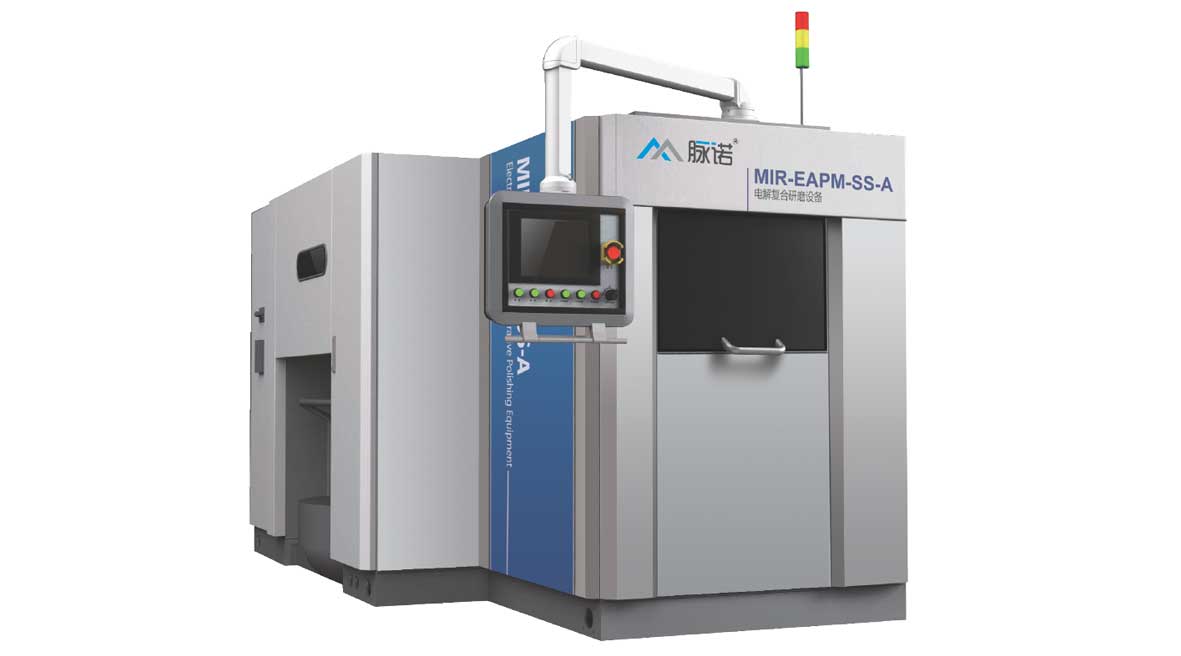

The equipment is a precision abrasive machine with high dimensional accuracy and stable quality, and can be used in batch production.

Comparison of electrochemical-mechanical abrasive polishing, electrochemical abrasive polishing, chemical abrasive polishing, mechanical abrasive polishing:

| Electrochemical-mechanical abrasive polishing | Electrochemical abrasive polishing | Chemical abrasive polishing | Mechanical abrasive polishing | |

| 1 | A process combining electrochemical and mechanical abrasive polishing that makes the metal surface smooth or even | Electrochemical abrasive polishing that makes the metal surface smooth or luminous | Chemical abrasive polishing that makes the metal surface smooth or luminous | Mechanical cutting, rubing, polishing and metal deformation that makes the metal surface smooth or even |

| 2 | Level the surface of the workpiece through both macro and micro ways to reduce the surface roughness | Level the surface of the workpiece through the micro way to reduce the surface roughness | Level the surface of the workpiece through the micro way to reduce the surface roughness | Level the surface of the workpiece through the macro way to reduce the surface roughness |

| 3 | No cold work hardened deformation layer (Beilby Layer), and no oxide film formed | Oxide film formed on the surface | Thin oxide film formed on the surface | Cold work hardened deformation layer (Beilby Layer) formed on the surface |

| 4 | The corrosion resistance of the polished surface is average, and the luminance is long lasting | The corrosion resistance of the polished surface is good, and the luminance is long lasting | The corrosion resistance of the polished surface is average, and the luminance is average | The corrosion resistance of the polished surface is poor, and the luminance does not last |

| 5 | Can achieve 12k high mirror effect, surface roughness can reach nm level | Cannot achieve 8k mirror effect, surface roughness limit is under 0.1um | Cannot achieve mirror effect, surface roughness does not change | Can achieve 8k or even 12k high mirror effect, surface roughness can be lower than 0.01um |

| 6 | Can see hidden defects in the lower layer of the product surface | Can see hidden defects in the lower layer of the product surface | Possible to see hidden defects in the lower layer of the product surface | Will cover the defects on the product surface |

| 7 | Polished surface without stress and debris | Polished surface without stress and debris | Polished surface without stress and debris | Polished surface is stressed and contains polishing abrasives |

| 8 | The surface of the processed workpiece is easy to clean, not easy to form dirt or breed bacteria | The surface of the processed workpiece is easy to clean, not easy to form dirt or breed bacteria | The surface of the processed workpiece is easy to clean, not easy to form dirt or breed bacteria | Not applicable |

| 9 | Can polish materials such as flat surface, curved surface, inner surface of small diameter cylinder | Can polish materials with complicated shape, small parts and thin thickness | Can polish materials with complicated shape, small parts, tiny aperture inner surface and thin thickness | Cannot polish materials with complicated shape, small parts and thin thickness |

| 10 | Fast processing speed, high productivity, allows mass production, easy to realize automation | Fast processing speed, high productivity, allows mass production, easy to realize automation | Fast processing speed, high productivity, allows mass production, easy to realize automation | Low processing speed, low productivity, hard to realize mass production or automation |

| 11 | No dust or waste gas generated from the polishing process | Dust and waste gas will be generated from the polishing process | Waste water and gas will be generated from the polishing process | Dust will be generated from the polishing process |

| 12 | Use neutral salt as polishing solution | Use strong acid as polishing solution | Use strong acid as polishing solution, high temperature | Use physical polishing materials |

| 13 | The polishing method is suitable for any metal material | The polishing method is suitable for any metal material | The polishing method is suitable for materials such as stainless steel | Difficult to conduct mechanical polishing on hard metal materials |

| 14 | Low requirements on materials | Certain requirements on materials | Certain requirements on materials | Low requirements on materials |

| 15 | The composition and structure of the base material have certain influence on the polishing effect | The composition and structure of the base material have large influence on the polishing effect | The composition and structure of the base material have large influence on the polishing effect | The base material has little influence on the polishing effect |

| 16 | The labor intensity of the operation is low and the process requires workers to have skills | The labor intensity of the operation is average and the process has low requirements on the skills of workers | The labor intensity of the operation is average and the process has high requirements on the skills of workers | The labor intensity of the operation is high and the process has high requirements on the skills of workers |

5. 摘要 Summary 鉴于大量的影响参数和由此产...

4.3 电化学(阳极)清洗 Electrochemical (anod...

4.2 化学去除方法 Methods of chemical remova ...

3. 清洁和维护 腔室 Cleaning and m...

时间:2023年9月22日 地址:浙江温州温德姆酒...

Equipment Sales:

Mr. Wang: +86-15921887786

Mr. Li: +86-18017268222

Processing Service:

Ms. Zhang: 18001952488

Ms. Long:13386001718

Add.: No. 8 Xinshun Road, Zhujing Industrial Park, Zhujing Town, Jinshan, Shanghai, China

Email:

sales@mirrorglabrous.com