The equipment is developed and designed for cleaning the remaining stain on the products. The operator places a product at the starting position of the equipment at the material loading and unloading level. The automated conveying unit of the equipment conveys the product to the corresponding cleaning area for cleaning, and then, the transfer robot transfers the product to each cleaning tank for ultrasonic cleaning, bubbling rinsing, ultrasonic rinsing and other processes. After completion, the product is transferred to the tunnel section for spray cleaning, wind shear water removal, hot air circulation drying, and fan cooling, and finally, discharge at the manual loading and unloading level, in order to complete the product cleaning, drying, cooling, and discharging process. The whole working process is controlled by PLC and monitored by the touch screen.

This cleaning equipment is mainly composed of ultrasonic generator, ultrasonic vibration plate, stainless steel cleaning tank, stainless steel liquid storage tank, stainless steel preheating water tank, filter circulation device, tunnel hot air drying system, automatic temperature control heating device, gantry single-arm mechanical arm (crane), parabolic lifting mechanism, slow-pulling dehydration mechanism, stainless steel pipeline system, automatic control and electrical control part, bracket chassis and painted shell.

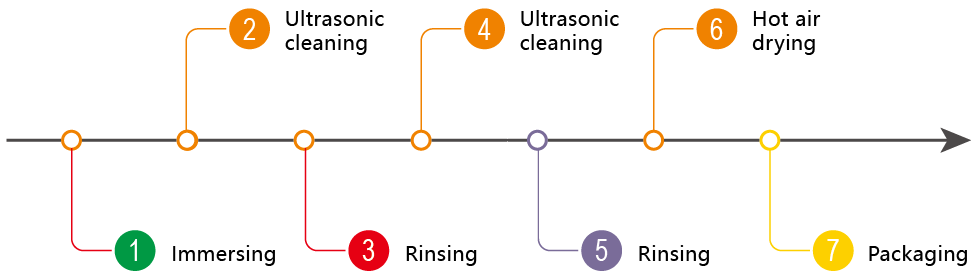

The typical process of ultrasonic cleaning:

5. 摘要 Summary 鉴于大量的影响参数和由此产...

4.3 电化学(阳极)清洗 Electrochemical (anod...

4.2 化学去除方法 Methods of chemical remova ...

3. 清洁和维护 腔室 Cleaning and m...

时间:2023年9月22日 地址:浙江温州温德姆酒...

Equipment Sales:

Mr. Wang: +86-15921887786

Mr. Li: +86-18017268222

Processing Service:

Ms. Zhang: 18001952488

Ms. Long:13386001718

Add.: No. 8 Xinshun Road, Zhujing Industrial Park, Zhujing Town, Jinshan, Shanghai, China

Email:

sales@mirrorglabrous.com